Mt Vision "Sienna Red" Clay

Initial tests with the local clay are presented.

Name

Mt Vision Sienna Red Clay

Collection in the Wild

The clay comes from decomposed granite found around the property in road cuts or similar excavation points. And most recently, with all the rain this year, small mud slumps.

It's called a primary clay because it is found in-situ, where it formed, within its parent granitic body. It turns out, when granite chemically decomposes due to water exposure over time, one of its natural byproducts is clay, a mineral.

For reference, clays that have been transported from their formation point, through water or wind forces, and deposited elsewhere, are called secondary clays. Most of the world's clays are secondary clays.

Processing

The raw material needs to be sieved to collect the clay minerals. A two step process is used. First, sieve using a 6mm mesh to remove the larger stones and to break up the clay clumps. Then, sieve again using a 60M mesh. Afterwards, let the clay settle in a bucket for a couple of days, periodically pouring off the water. Adding a flocculant like Epson Salt helps separate the clay and water and speeds the process. The result is a slip that can be dried further on plaster bats.

The picture below shows the clay in various states: (1) the clay slip in a metal bowl (post sieving and after removing much of the water), (2) the clay slip drying on a plaster slab, (3) the clay wedged and cut with a wire cutter, ready for throwing, (4) two small thrown bowls of bisque ware, (5) a test bar fired to Cone 6 and (6) , not clay, but two mugs glazed with the Mt Vision granite glaze in its natural state (no colorants).

Remarkably, without any additives, the clay is plastic (it passes the finger stretch test), throwable and matures in the kiln (Cone 6) with good glaze fit and no major defects, thus far!

Test bars are used to measure some characteristics of the clay. The results are discussed below.

Clay Property Test 1

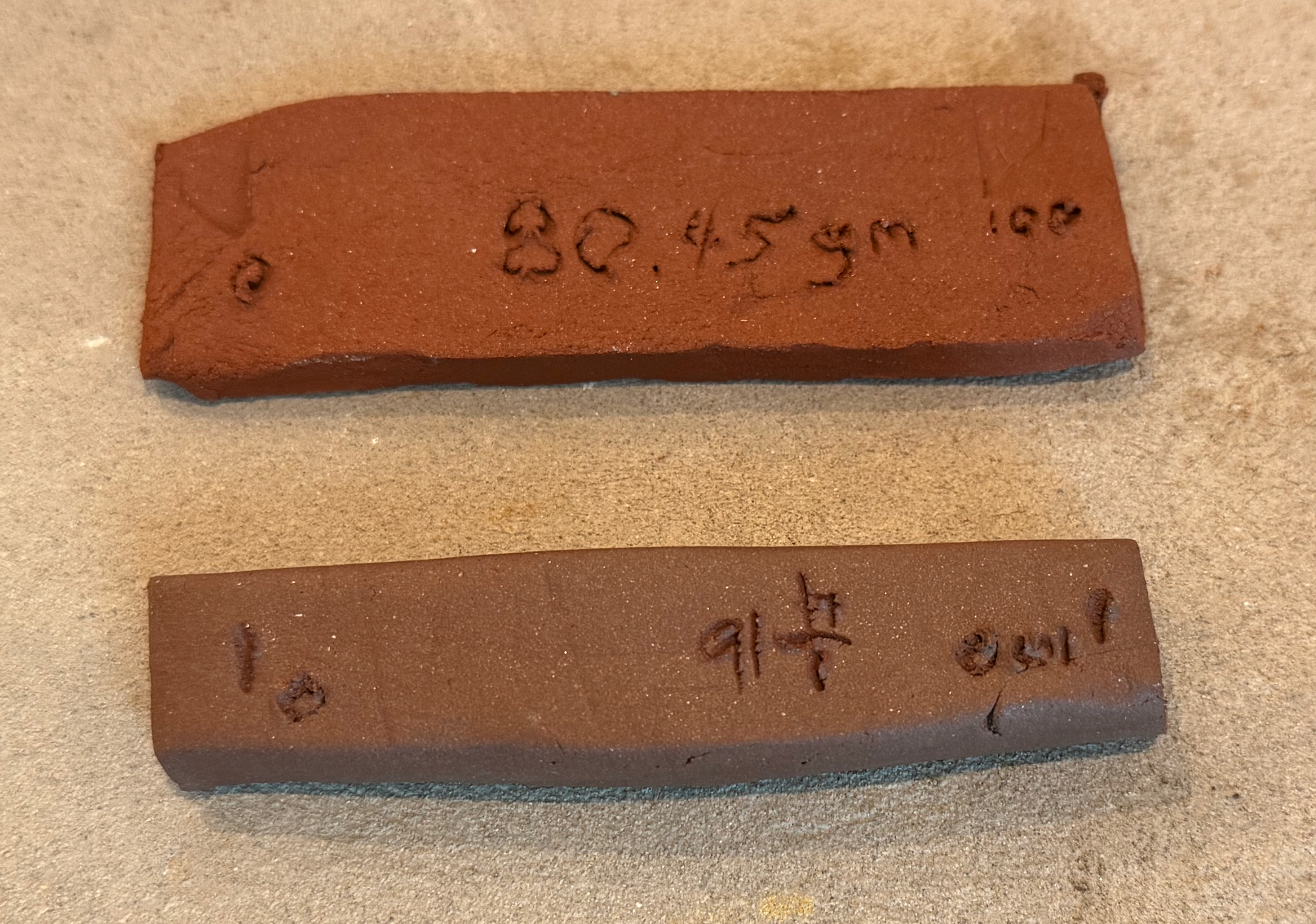

The test bar for this experiment was rectangular and thick and not very representative of the walls of a thrown piece of pottery (I missed the memo).

| State | Weight (gm) | % Water | Length (mm) | Shrinkage | Absorption % |

|---|---|---|---|---|---|

| Wet | 113 | - | 100 | - | - |

| Dry | 82 | 37.8% | 91 | 9.9% | - |

| Bisque 05 | 71 | 15.5% | 87 | 4.6% | - |

| Bisque 05 Wet | 82.5 | - | - | - | 16.1% |

| Cone 6 | 70 | - | 82 | 6.1% | - |

| Cone 6 Wet | 73 | - | - | - | 2.8% |

Below is a picture of test bar #1 fired to Cone 6 along with the corresponding initial glaze test, a pinch pot glazed with the Mt. Vision Granite "Tenmoku". This was an amazing first run!

Clay Property Test 2

The test bar #2 was formed flatter and thinner, being more closely aligned to a thrown piece of clay and therefore is presumably more representational.

| State | Weight (gm) | % Water | Length (mm) | Shrinkage | Absorption % |

|---|---|---|---|---|---|

| Wet | 80.5 | - | 100 | - | - |

| Dry | 64.1 | 25.5% | 90.50 | 10.5% | - |

| Bisque 05 | 54.0 | 18.7% | 85.5 | 5.8% | - |

| Bisque 05 Wet | 64.2 | - | - | - | 18.9% |

| Cone 6 | 53.5 | - | 83 | 3.0% | - |

| Cone 6 Wet | 59.2 | - | - | - | 10.7% |

In the end the difference between the two tests is not large except for the absorption % at Cone 6.

Analysis

Shrinkage

Val Cushing's notebook states for an average plastic clay suitable for wheel throwing, Wet to Dry shrinkage of ~6% is normal and another 6% - 8% is expected from Dry to Bisque, or 12% - 14% total.

Levy, Shibata & Shibata in their book Wild Clay give an example for a somewhat similar looking yellow clay with values Wet to Dry of 4.4% + Dry to Bisque of 6% = 10.4% shrinkage.

Purchased clay used in the studio, Sedona Red and Nara 5 from Aardvark and B-Mix 5 and Moroccan Sand from Laguna all report shrinkage of 12% at Cone 5.

We observed Test 1: 9.9% + 4.6% = 14.5% shrinkage Test 2: 10.5% + 5.8% = 16.3% shrinkage, so total shrinkage is roughly aligned, albeit on the high end.

Water Content

Levy, Shibata & Shibata record 16% water in their clay example and we observed Test 1: 38% and Test 2: 26%. This is higher, but given my small experience, I don't know yet how important this may be.

Absorption

Val Cushing states absorption of <5% is expected at any temperature while Levy, Shibata & Shibata recored 22% at Cone 04, but < 2% at Cone 10.

Purchased clay used in the studio report variable shrinkage, namely, Sedona Red 3.5% and Nara 5 1.1% from Aardvark and B-Mix 5 2.5% and Moroccan Sand ~1% from Laguna at Cone 5.

We measured Test 1: 16% at Cone 05 and 3% at Cone 6 and Test 2: 19% at Cone 05 and 11% at Cone 6.

I was expecting Test 1 and Test 2 absorption to be similar at Cone 6, but they clearly are not. And I just noticed the final color of the clay is different between Test 1 and Test 2 fired at Cone 6, so there are differences between clay batches themselves ... of course (>_<). If Test 2 is an outlier, then the clay is "in the range", based on Test 1. More testing will determine if this is true.

Clay Classification

Levy, Shibata & Shibata note the following general characteristics for clay bodies:

Throwing clay bodies

- Shrinkage: high

- Water absorption: low

- Texture: fine

- Plasticity: high

Hand-building and slab bodies

- Shrinkage: medium

- Water absorption: medium

- Texture: medium

- Plasticity: medium

Given the test results above, we could classify the Mt. Vision Clay as a throwing clay body with:

- Shrinkage: High - Because it roughly meets Cushing's shrinkage range for a plastic throwing clay and is in fact slightly higher than his datapoint.

- Water absorption: Low? Medium? High? More tests will be necessary to know for sure. But not Low if Test 2 is indicative.

- Texture: Fine - Observationally it is a fine particle clay, more like a Porcelain or B-mix than a brown clay with more grog like Sedona Red, for example.

- Plasticity: High - Observationally it's very plastic, more so than simply passing the finger stretch test. In fact, if anything, it could be too plastic. It's very sticky. But it does easily wedge into a uniform clay body.

While this is a "nice" result (perhaps even coaxed you might argue), the fact of the matter is, without modification, the clay:

- Is easily wedged and thrown, even for large pieces

- Matures in the kiln at Cone 6 and appears vitrified (it needs stress testing)

- Holds a glaze

- Has not exhibited any major bisque or mid-fire defects (thus far).

It is also iron rich, as you can tell from its color, being a delightful red at bisque Cone 05 and turning a Sienna Red at Cone 6.

It's still early days, of course, but the results are very promising. More to come including pictures and further test results.